Sound Generation Mechanism of Piezoelectric Buzzer

The piezoelectric buzzer is used to generate alarms and electronic sounds. A device to transmit signals to people and is widely used in household appliances, consumer products, and other devices for people’s livelihood, as well as automotive and industrial equipment.

What is the sound generation mechanism of the piezoelectric buzzer?

Recognizing sound

Sound is the vibration of air, such as alarms, fire alarms, alarm clocks, etc. Air vibrations sound sources cause changes in air pressure sound waves, which are transmitted to the ear and cause the eardrum to vibrate, thus being recognized as sound.

The sound loudness is usually said to be the sound pressure level, and the pitch is the frequency. Generally, the minimum loudness of sound that can be heard as 0dB (20μPa) is the benchmark of sound pressure. Futtrobuzzer’s sound components are approximately 70 to 90dB (at 10cm).

| Whispering | 20dB |

| Normal Dialogue | 60dB |

| Light rail sound | 100dB |

However, if the distance from the sound source is far, the sound will also become smaller. Therefore, to meet certain sound pressure regulations, the product needs to determine the distance from the sound source and the required sound pressure.

The frequency band (audible frequency range) in which the human ear can hear “sound” is generally “20Hz to 20,000Hz”. Among them, the “2kHz to 4kHz” area of the sound can be heard most effectively, so the sound components use “2kHz to 4kHz” more often.

Types of Acoustic Elements

In fact, many of the commonly used sound components are mechanical. That is the way to produce sound by applying mechanical impact to the sound source, such as bicycle bells, etc.; electronic sound components are the way to make the sound source vibrate by applying electrical signals such as voltage and current.

Piezoelectric sound components, on the other hand, are more and more widely used in various equipment and instruments in modern life and work because of their low power consumption, easy driving, simple and reliable structure, lightweight and easy thinning.

Piezoelectric sound element structure and principle

The piezoelectric sound element must be placed into a piezoelectric vibration plate. This is a simple structure consisting of piezoelectric ceramics that have formed electrodes bonded to brass, nickel, and other metal plates.

When a voltage is applied to the piezoelectric vibrating plate, the piezoelectric ceramic will pull up, but the bonded metal plate will not stretch but bend. (a) When the reverse voltage is applied, it will bend in the opposite direction. (b)

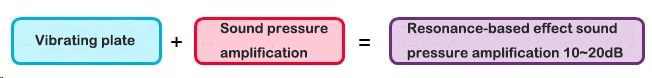

A signal with mutually varying input voltage directions will repeatedly alternate between (a) and (b), producing sound waves (c). Piezoelectric sound components usually have housings, which serve not only for protection but mainly because of the resonance effect of the housing, which allows the component to produce a louder sound.

Based on the resonance effect, when the resonant frequency fo of the vibration plate is close to the resonant frequency fcav inside the shell, the sound pressure can be increased by 10 to 20dB.

fo (resonant frequency), the most effective vibration frequency of the vibration plate.

fcav (resonant frequency), the resonant frequency inside the housing is determined by the size of the housing, the size of the sound emitting hole.

The driving circuits for piezoelectric sound elements are self-drive circuits and external-drive circuits.

The popularity of microcomputers has made the external drive type mainstream (above). In this case, an external signal such as IC is input to drive the sound. The sounding frequency is the external signal source frequency.

Self-drive vibration type is a component with transistors, resistors together to form an oscillation circuit, the application of DC voltage to trigger vibration and sound. In this case, the sounding frequency is the resonant frequency of the oscillating plate.