What Are the Common Quality Problems with SMD Buzzer Applications?

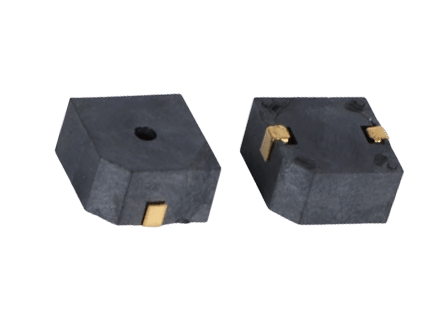

SMD Buzzer The buzzer is a structured electronic device that emits the alarm tone “tick, tick, tick” and is widely used in cars, communications, white goods, medical treatment, intelligent security, and other electronic devices as a pronunciation device. The SMD buzzer is a piezoelectric buzzer with excellent BTL output and a dedicated optocoupler circuit, which has been upgraded with a new core concept and processing expertise.

Active SMD buzzer Make the substance the same and all kinds of professional skills index value is a good improvement; The IC has positive frequency tracking and temperature compensation role so that the buzzer is not easy due to the transformation of the working voltage and condition temperature and cause frequency drift; Accept SOP-8 post chip package, can thoroughly accept SMD components and SMT processing process, replace most of the inductor variable voltage driver, greatly Development of high efficiency in manufacturing, sinking product costs.

Here below are some points about the common quality problems with SMD buzzer applications.

The categorization and processing of SMD buzzer

Two types of buzzers, the SMD buzzer, and the pin plug buzzer.

SMD buzzer is used for surface mount, according to SMT mount, reflow oven to complete the electric welding requirements, welding method is simple.

Needle plug buzzer then according to the PCBA electric welding hole, wave soldering machine to complete the electric welding requirements, processing technology perfect.

Today’s processing technology also has the installation of the two processing technology, we call it solder-free welding buzzer, some volume is very large buzzer if according to SMT solder welding, solder welding credibility can not reach the automotive-grade regulations, thus causing solder-free welding buzzer, according to the locking way buckle on the PCBA, this kind of structure can complete without solder welding, smooth and reliable requirements.

The SMD buzzer is small and slim and has a square shape. Both piezoelectric and magnetic induction buzzers can be subdivided into chip buzzers, so their main use is the same as piezoelectric and magnetic induction, with the key effect being articulation.

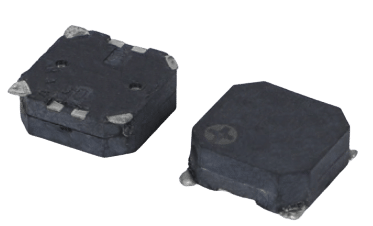

Identification of SMD buzzer pin efficacy

Inductive SMD buzzer square generally has 3~4 solder holes, but only 2 solder holes are connected with the inner electromagnetic coil, the other 2 solder feet are designed for better merchandise soldering flat paste and solid and scheme.

For the side phonetic pronunciation of the SMD buzzer, the 2 feet directly opposite the phonetic pronunciation hole are generally positive and negative.

However, because some customers have not anticipated the design of the route, we also change our product pin rotation according to the customer’s route.

As a result, the same product may have a variety of different rotational characteristics, so we do not strongly recommend checking the positive and negative of a product based on its appearance.

If the customer is designing a solution or if it is necessary to use such a buzzer, anticipate and design a solution first.

The test product can be identified according to the positive and negative signs in the manual; you can also use a digital multimeter to adjust to the resistor file and connect one end of the product appearance with or sign, this end is the positive level of the product, the other stylus is successively connected to the other solder hole and connected to all afoot with resistor display information, it can be clear that this end is the negative level of the product.

Main applications for SMD buzzers

SMD buzzer is mainly used for various electric phones, digital clocks, medical equipment, electronic products, small toys, corporate office equipment, notebook computers, microwave oven heating, central air conditioning, household appliances, weapons, and equipment controllers.

The main uses of the piezoelectric buzzer are mobile phones, handheld music playing software, electronic dictionaries, digital recorders, digital cameras, e-books/various handheld weaponry.

Piezoelectric alarm systems are mainly used for: various alarm devices, motorbikes, cars, information security, warehouses, buildings, weapons, and equipment.

Inductive buzzers are mainly used for: various electric phones, digital clocks, medical equipment, electronic products, small toys, corporate office weaponry, notebook computers, microwave heating, central air conditioning, household appliances, weaponry controllers.

Foot-operated buzzers are mainly used for: medical equipment, corporate office equipment, household appliances, weapon controllers.

The common problems with SMD buzzer practical application

If the welding temperature is too high, it is very easy to cause deformation of the buzzer case and loosening of the needle angle, resulting in no sound or a small sound;

If the starting voltage of the buzzer is a little low or large, it is very easy to have a small sound or a sandy sound during the whole application;

The buzzer is stored and placed for a period of time and then the sound is small, and after a period of application, it becomes all normal. Such conditions may be the result of the buzzer being endangered by the wet and cold natural environment, and attention must be paid to waterproofing.

When the buzzer is working on the PCB board, there will be a change of tone or no sound, but there is no problem removing the single test. This condition may be caused by the buzzer being affected by electromagnetic fields.